Dynamic loading and stress analysis on crankshaft of reciprocating mud pump

4.9 (616) · € 14.00 · Auf Lager

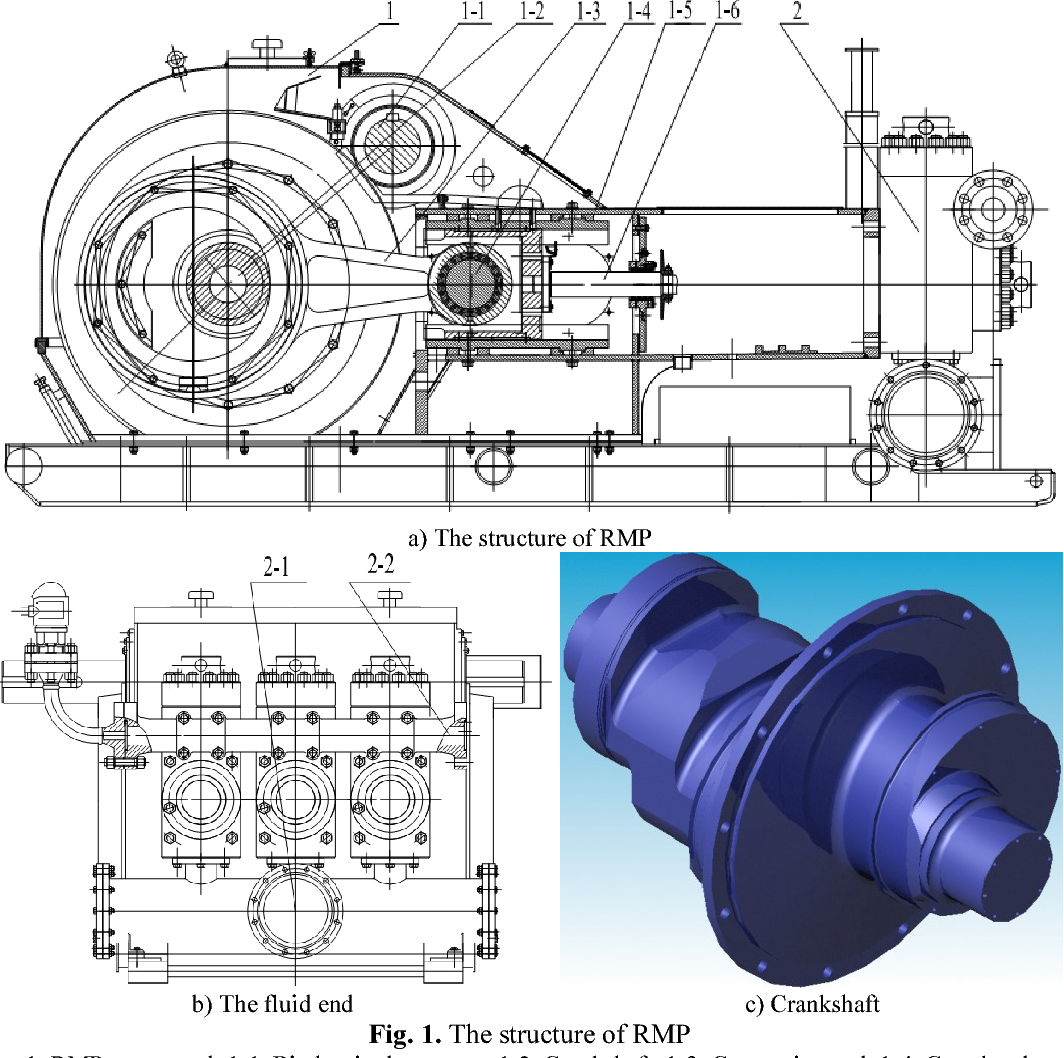

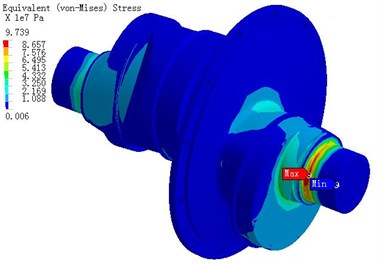

Computation model of crankshaft was built and the dynamic characteristics of crankshaft were studied. FEM was performed to obtain the maximum main stress, the minimum main stress and the Mises stress at three kinds of critical working conditions of crankshaft. Through movement analysis and computation for various components of reciprocating mud pump (RMP), the loads of crankshaft were obtained. The maximum stress of crankshaft at the three kinds of dangerous operating modes was obtained from the FEM stress analysis. It is located in the critical region and the location belongs to the dangerous position in most of the fracture crankshafts. The FEM stress analysis results are very valuable in guiding actual application development for intelligence optimization design of RMP.

amp; (%)

Fatigue Life and Stress Analysis of the Crankshaft of a Single Cylinder Diesel Engine under Variable Forces and Speeds

Role of Bearings in New Generation Automotive Vehicles: Powertrain

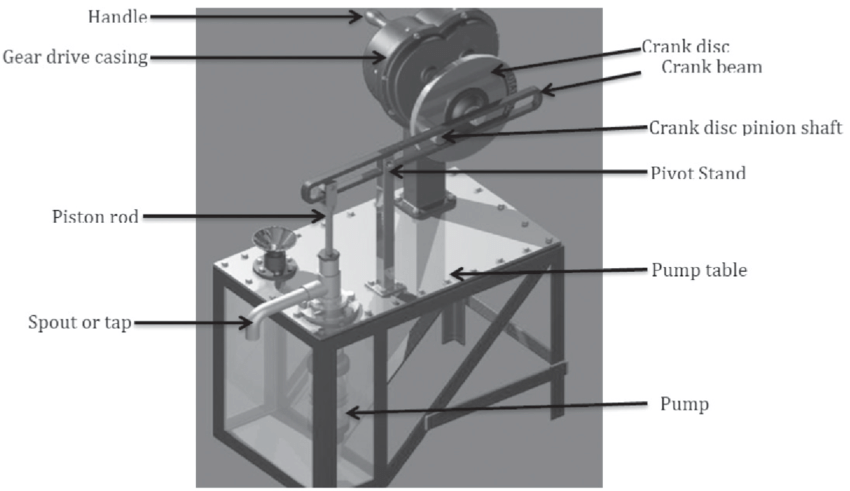

Positive Displacement Pumps: A Comprehensive Guide – Piping and Interface Engineering

Engineering Definitions A-L by Zach Arneil - Issuu

Dynamic loading and stress analysis on crankshaft of reciprocating mud pump

Fatigue Life and Stress Analysis of the Crankshaft of a Single Cylinder Diesel Engine under Variable Forces and Speeds

Dynamic loading and stress analysis on crankshaft of reciprocating mud pump - Extrica

Dynamic simulation and stress analysis for reciprocating compressor crankshaft - Bin-yan Yu, Quan-ke Feng, Xiao-ling Yu, 2013