- Startseite

- heat exchanger

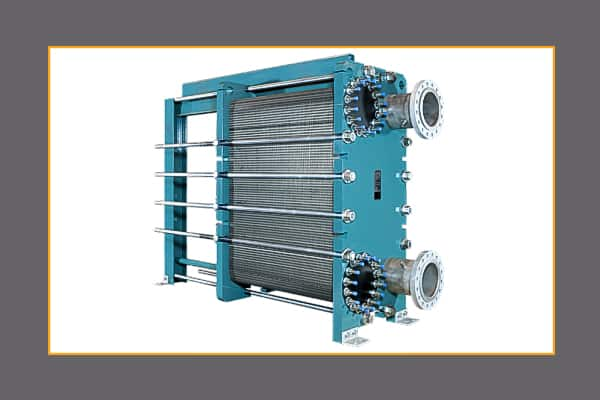

- How To Size A Waterside Economizer Part 5: Why Plate & Frame Heat Exchangers Are Preferred —

How To Size A Waterside Economizer Part 5: Why Plate & Frame Heat Exchangers Are Preferred —

4.7 (244) · € 23.00 · Auf Lager

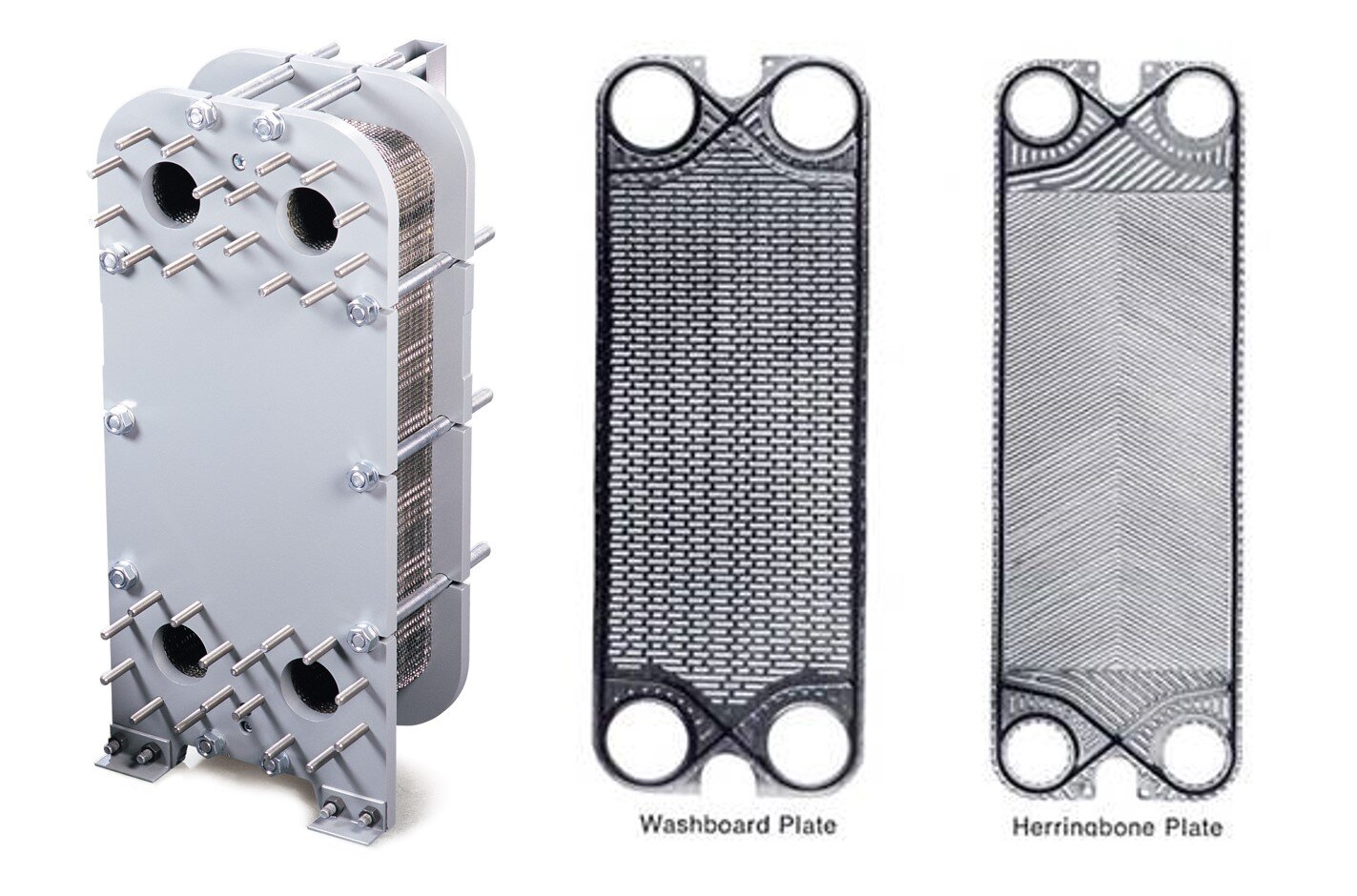

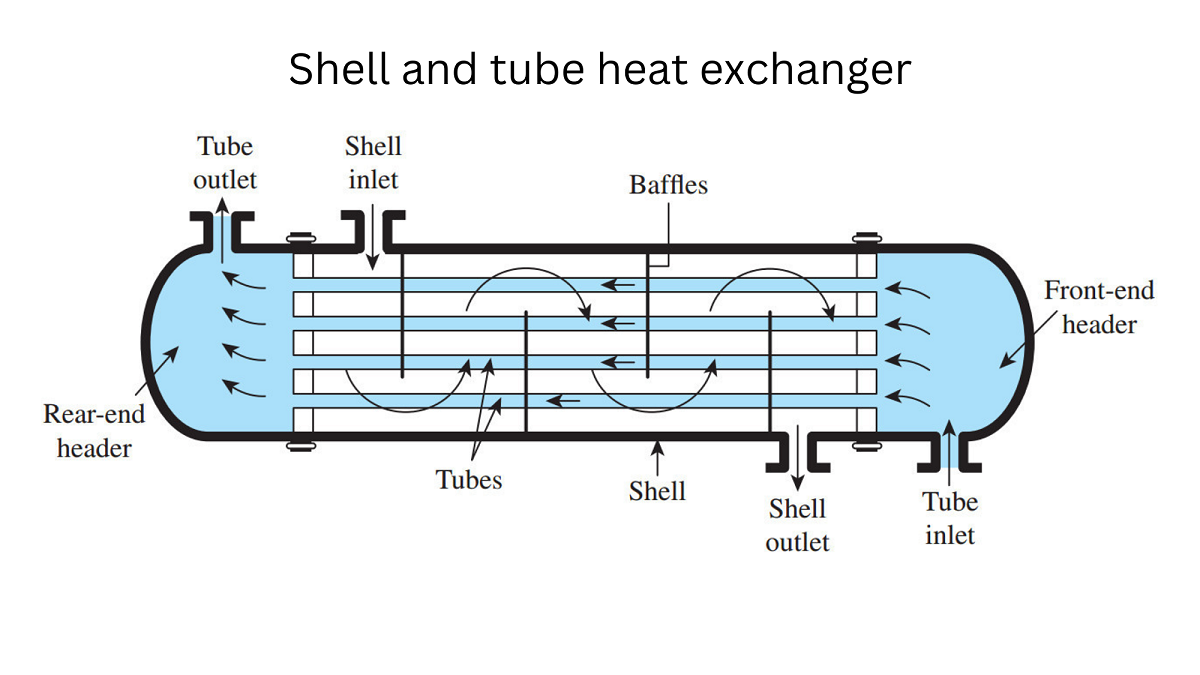

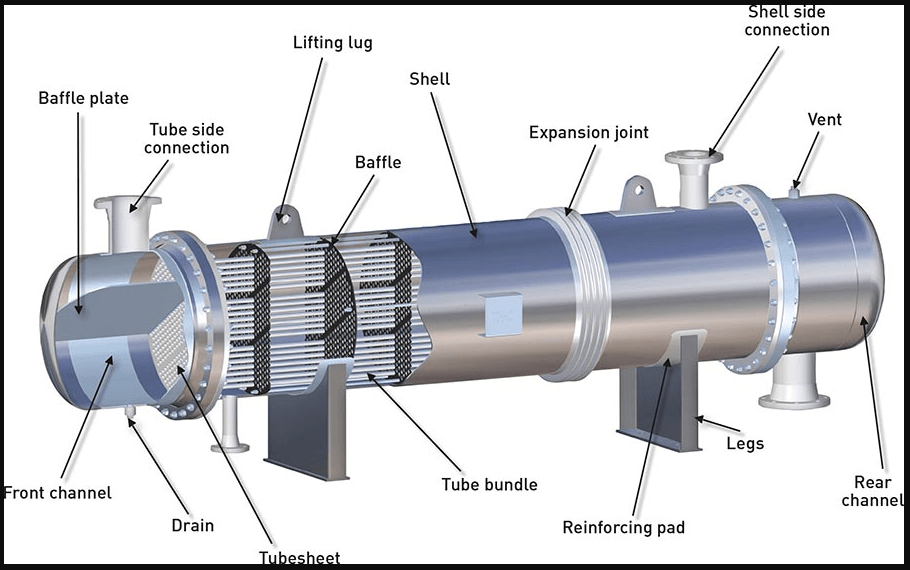

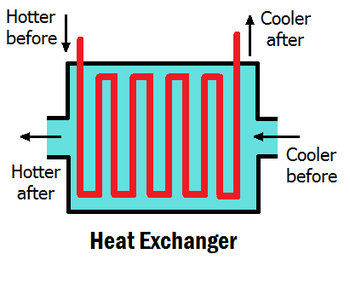

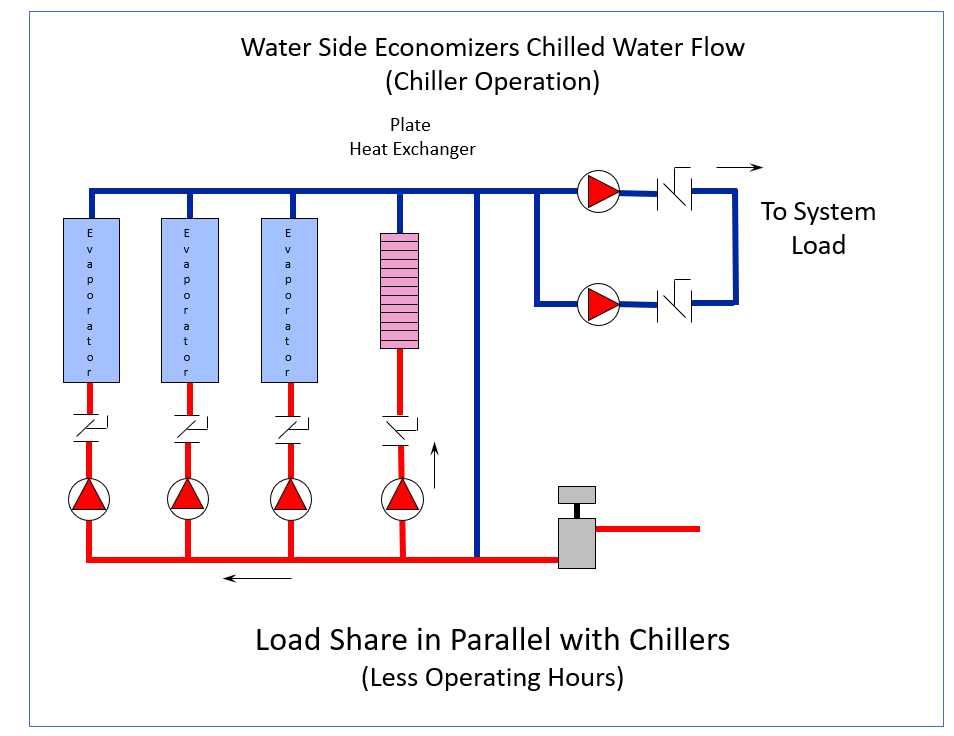

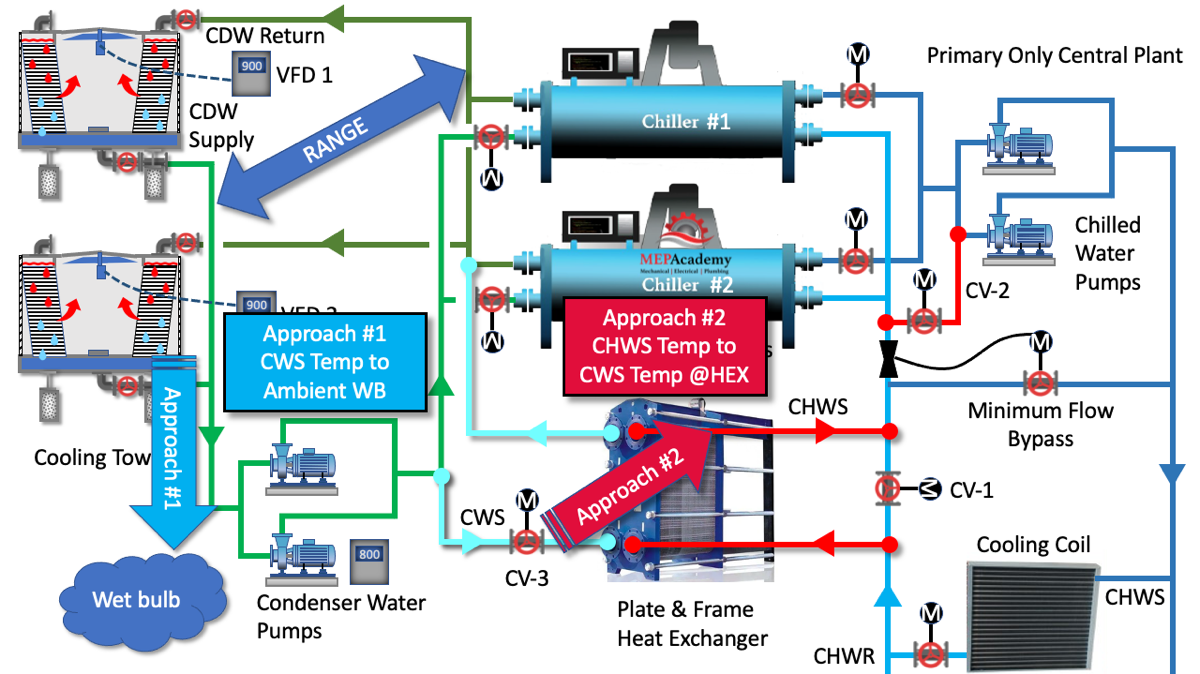

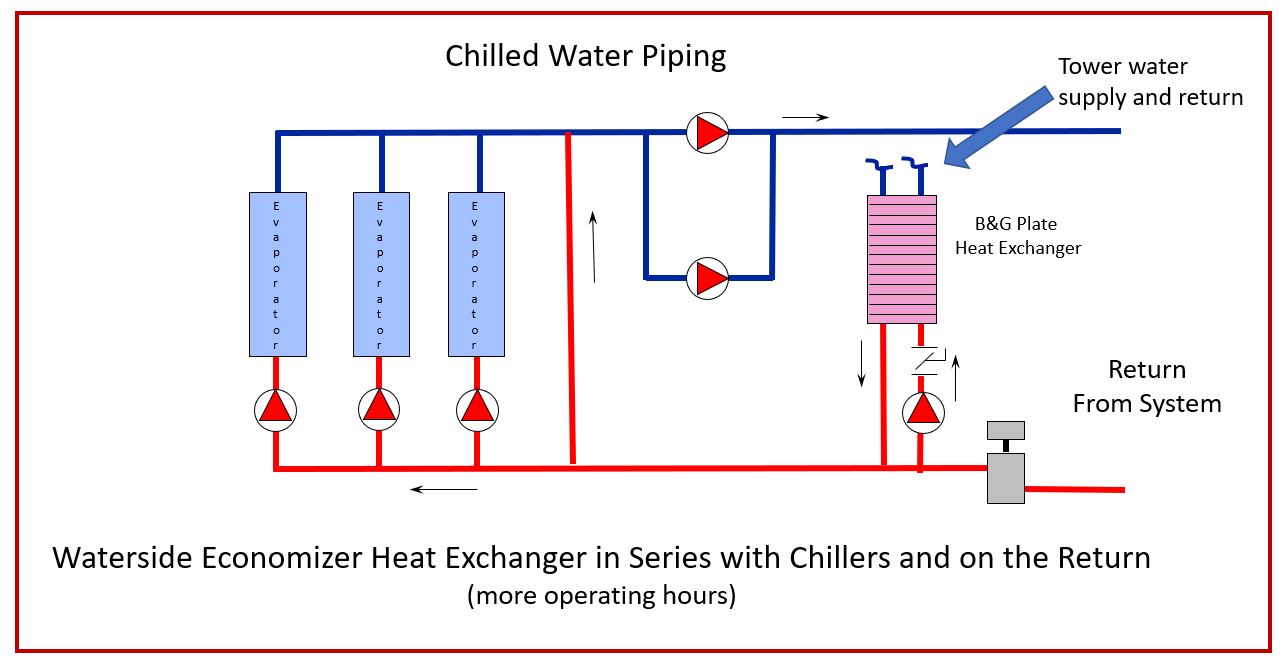

Waterside economizing typically involves the transfer of BTUs from an open loop cooling tower system to a closed loop chilled water system. Since these two hydronic systems must remain separate so we do not foul the chilled water systems, a heat exchanger is required to prevent mixing of the flu

Waterside Economizers Part 5: Heat Exchanger Location Options

How to design & control waterside economizers - Document - Gale Academic OneFile

Water Side Economizer Heat Exchanger Sizing and Selection

PDF) CFD analysis of an economizer for heat transfer enhancement using serrated finned tube equipped with variable fin segments

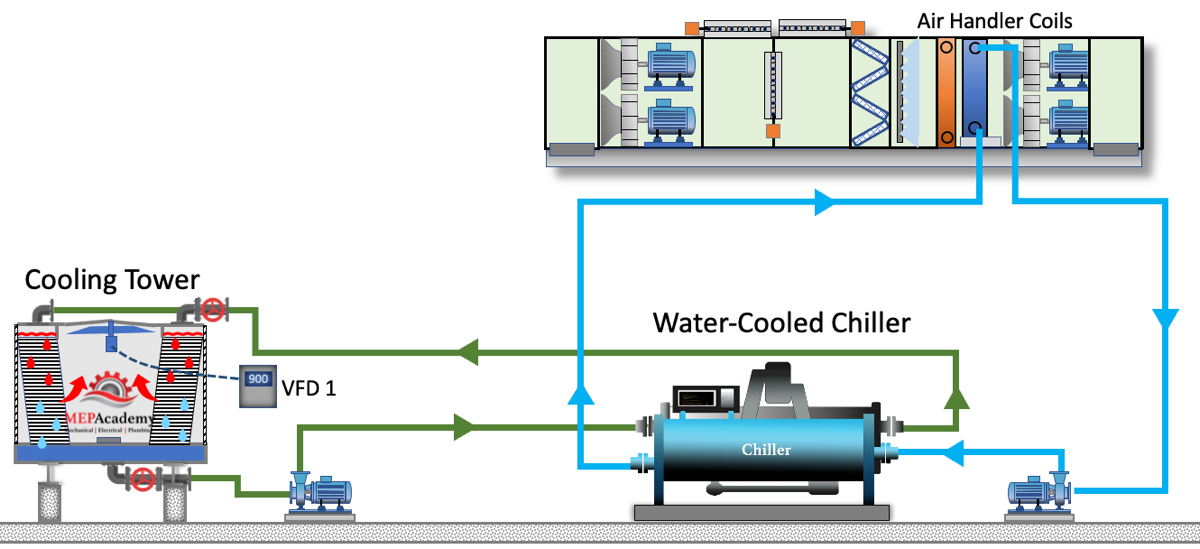

How Waterside Economizers Work - MEP Academy

How Waterside Economizers Work - MEP Academy

Waterside Economizers Part 5: Heat Exchanger Location Options

How Waterside Economizers Work - MEP Academy

Applications Engineering Manual - Chilled-Water VAV - Index of

Global trends, performance metrics, and energy reduction measures in datacom facilities - ScienceDirect

How to design & control waterside economizers - Document - Gale Academic OneFile

How To Size A Waterside Economizer Part 4: Chilled Water Piping Requirements —